What are Printed Papers And How Do They Make A Difference?

With the depleting health of the environment and rising concerns about the future, brands have started taking initiatives for a better tomorrow. One of the important steps includes converting your brand into an eco-conscious entity.

Research shows that people are more inclined towards brands that keep their packaging eco-friendly. Therefore, turning the course of your brand towards sustainable packaging solutions is one of the best tactics to increase customer traffic.

Printed Papers are an excellent substitute for your regular plastics. We make them using our skills and experience — using natural or recycled materials, eco-friendly inks, coatings, and special additives to amplify the strength and enhance the practicality of these papers.

Whether it’s for industrial use, retail packaging, or food packaging, we provide you with the best quality and a smooth packaging experience. For a significant decrease in the cost price, we recommend you buy bulk printed paper.

How Do We Manufacture Your Printed Papers?

Manufacturing our papers for prints consists of easy-to-follow steps. We will guide you through them here, and for live inspection, you can visit our site and check for yourself. These processes include:

- Material selection

- Sheet production

- Prints & Coatings

We take recycled paper, wood pulp, or fibres from bagasse or bamboo. These materials make your paper biodegradable and recyclable, thereby reducing the carbon footprint and environmental impact.

Sheet Formation

The next step after material selection is the sheet formation. Sheets are then sent forward for prints and finishing touches. There are two processes by which it is done:

- Mechanical process

- Chemical process

In the mechanical process, the wood chips are ground with large grinding machines. The pulp is diluted with water, spread on mesh screens to dry and filter, passed through rollers for double drying, and here it is — your brown sheets are ready.

Whereas, in the chemical process, sodium hydroxide and sodium sulfide are used. They break down lignin and convert it into cellulose fibres. Now you have sulfate or kraft pulp in white colour.

Print Your Fantasies Over The Printed Paper Roll To Increase The Shelf Impact

Printed Kraft Paper is in demand for enhanced branding and customer experience. You can print your brand name, logos, and pretty patterns to catch the attention of your potential customers. Brands print pictures, creative designs, or simply dye the paper in their signature colours to be recognised from afar. For that, we offer the following printing options:

- Offset printing: Brands prefer it for sharp detail and long runs. Although the setup cost is high and not the best for rough surfaces but it is still doable and cost-effective.

- Flexographic printing: It is preferable if the design is simple, for long runs in a short time, and works well with porous surfaces like kraft.

- Digital printing: Best for short runs and efficient detailing. As there are no extra plates required, the design is transferred directly on the paper, and they come out pocket-friendly.

- Screen printing: Use this to have designs in bold and vibrant colours, whether it is a flat, thick, or irregular/uneven surface. We recommend it for short runs.

Furthermore, we provide you with two colour systems: PMS & CMYK. Pantone Matching System (PMS) provides you with consistency for your signature designs. You can get the exact shade using the code to refer to in the Pantone library. This can come out costly if the design is complex, requiring multiple shades.

Therefore, if consistency is not a concern and you require a wide range of hues and shades under the budget, we recommend using CMYK. This system uses four colours: Cyan, Magenta, Yellow, and Key (Black).

Tip: To get them cheaply, buy printed paper wholesale.

Secret Ingredients To Enhance The Aesthetic Functionality Of Your Printed Packaging Paper

Moreover, you can enhance the surface texture, aesthetic appeal, and functionality of your branded printed paper by using our add-ons. These include:

- Coatings: We use these coatings to enhance the textural appearance as well as amplify the protective features. These coatings include matte, gloss, and wax coatings.

- Additives: Our additives are used to add to the strength and functionality of the papers. It is done by using wet strength resins (for absorbing more moisture and grease and to save from the mess) and dry strength resins (to add maximum tear resistance).

- Beautification: Similarly, we use embossing, debossing, and foiling to turn heads, add emphasis, and magnify your brand image.

We use these add-ons to provide you with the best printed paper, exclusively at TheCosmeticsBoxesUK.

Why Should You Go With Customisation?

Customisation is an important element of product packaging. Your packaging papers are not just a wrapping; they are representatives of your brand. The first impression must be impactful enough to get you not just buyers, but customers. Here is a breakdown of how customisation is important.

Protect & Preserve The Product

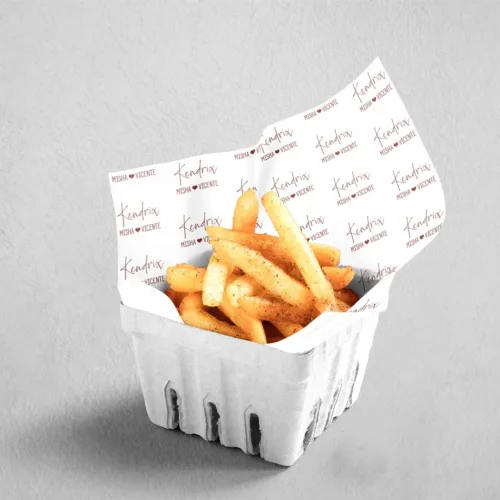

These papers are used as bags or as printed papers for wrapping: they need to be strong and hygienic. We create strong, tear-resistant, hygienic, and chemical-free papers to prove our reliability and provide you with security. These papers, when wrapped around the food, provide exceptional moisture resistance, keeping the food from getting soggy or the grease from leaking. Therefore, you get to give your customers a clean, mess-free, sophisticated customer experience.

Brand & Product Presentation

Similarly, Product packaging is the first thing to be noticed; make this first impression count. We provide you with our team of experts to create alluring designs, and these custom printed paper designs would get you a huge traffic of potential customers. Let our experts surprise you or share your personalised designs with us. You can also take inspiration from our pre-prepared templates and save time.

How Do We Make Sure That The Custom-Printed Papers Are Food-Grade And Eco-Friendly?

We understand your concerns, as these papers come in direct contact with food items as well. Your health is important and considered here. That is why we make sure that these Food Packaging papers are:

- Food-grade (paper & inks)

- Odourless & Tasteless

- Non-toxic/Chemical-free

- Hygienic (manufactured in a controlled environment)

Furthermore, you can have a look at our certificates to lock your trust in us. We make sure that the packaging is compliant with:

- UK/EU Food Contact Law

- BRCGS

- ISO/HACCP

Additionally, the wine glass and fork logo is important for showcasing the food-gradeability of your Printed Papers, along with the FSC® and EN 13432 eco-labels. Now you know that we provide food-grade and eco-friendly papers. So, there is no reason to wait — contact our team and order cheap printed papers online!

What Else Do We Have To Offer?

Here we are, to the most important part of the content: what do we have to offer to make you contact us? Well, it is simple.

We provide you with the best packaging services: a variety of customisation options, a skilled and dedicated team of experts, safe and quick transits, transparent deals, ideal offers, and reliability, along with responsibility.

You can further check our types of Printed Papers that we provide:

- Butcher Paper

- Cheese Paper

- Deli Paper

- Kraft Paper

- Food Paper

- Butter Paper

- Fry Paper

- Freezer Paper

- Hot Paper

- Burger Paper

- Pizza Paper

- Bangle Paper

- Sandwich Paper

- Greaseproof Paper

- Food Basket Liner Paper

- Parchment Paper

Click on the item, and the link will take you directly to the page where you can find the details for these options. Best of luck!

We are looking forward to our thrilling collaboration ahead.